Giving robots a human touch

Increasing the level of automation – with the intelligent compensation module for robots

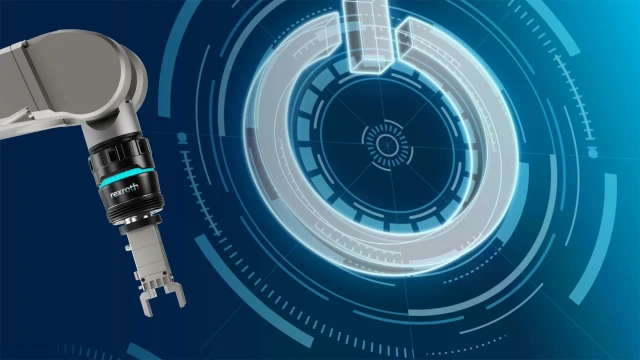

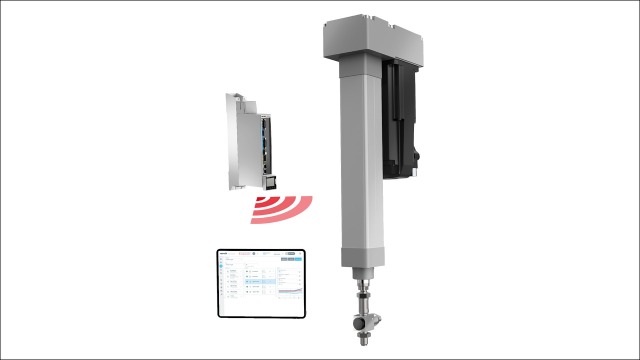

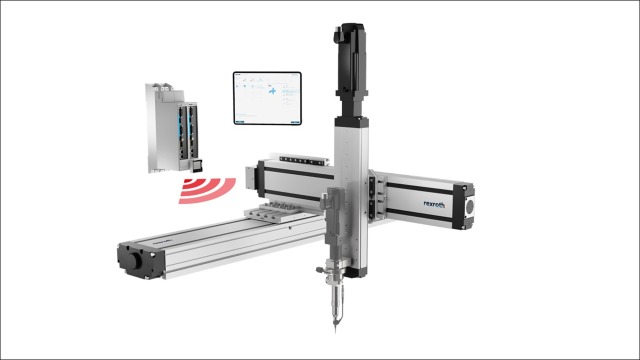

Automating complex processes with ease and implementing new applications – no problem with the Smart Flex Effector, our sensor-based, easily retrofittable compensation module. By actively measuring position data in six degrees of freedom, the end effector gives industrial robots the precision and sensitivity of a human hand, thus opening up completely new possibilities in factory automation.

Areas of application

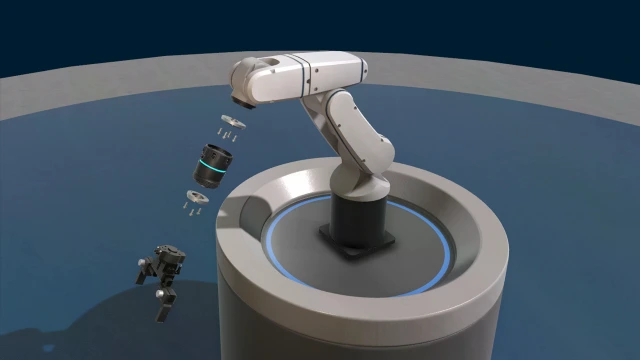

The Smart Flex Effector can be fitted to all typical robots such as articulated robots, linear robots or cobots and is compatible with a wide range of grippers. It opens up completely new approaches in factory automation. It can be used virtually anywhere: In the electronics, automotive or packaging industries, in battery production, in mechanical engineering or in metal construction.

The Smart Flex Effector impresses with four unique selling points shown here using a simple joining process as an example:

Contact us now

Get to know our smart, ready-to-use solution packages and find the right solution for your future production with us.

We look forward to your inquiry and will be happy to advise you!